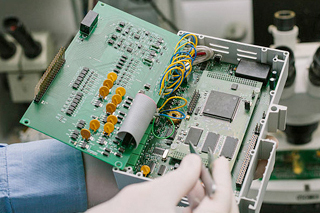

Premium Circuit Board Assembly and System-Level Manufacturing.

Quality Circuit Board Design

Lorser provides state-of-the-art, end-to-end product design and testing for complex, system-level products across eight industries: medical, communications, defense and aerospace, industrial, computing and storage, multimedia, automotive, oil and gas.

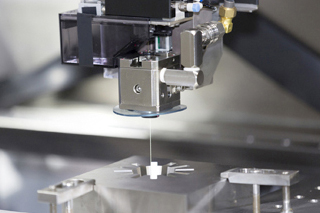

Fully Automated Production

6 Fully Automated Production Lines; 75,000 Placements-Per-Hour Throughput with 2 Pick-And-Place M-20 I-Pulse Machines In-Line; Controlled Inventory; Supply Chain Management; 23000 sf Stand Alone Class A State Of The Art Facility Environmentally Controlled.

Quick Turnaround Delivery

From prototyping low volume high mix to high volume cost optimized production, Lorser provides timely delivery and quality advanced engineering for PCBA and SMT, with 3 and 5 day quick turn, or standard turn for all consignment and turn-key projects.

Lorser Industries has been a great and valuable manufacturing partner for Raveon Technologies Corporation. Our products are complex and have very high density circuits, and yet the quality and delivery time Lorser is able to provide Raveon is excellent. Working with the talented folks at Lorser makes kicking off new product production very easy. Lorser is a great manufacturing partner.

John SonnenbergServices

DESIGN & ENGINEERING

Lorser has 500+ product designs and more than 30 years of experience in system software engineering. We have design expertise for each of our key industry segments and each component division, providing our customers with a broad range of market & technology expertise.

SUPPLY CHAIN MANAGEMENT

Customers experience immediate benefits from Lorser’s global supply chain expertise for contract manufacturing, including access to a broad range of qualified suppliers, personnel deployed in all regions, asset utilization and supply chain simplification.

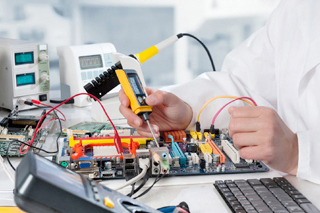

FUNCTIONAL TESTING AND TEST SYSTEM DEVELOPMENT

Lorser develops comprehensive, integrated and cost effective test strategies at component, sub-assembly and finished product levels using customer and industry standard hardware and software test platforms.

QUALITY AT LORSER

Lorser’s Quality system is the result of 30 years of refinement, best practices, processes and tools for contract manufacturing. Lorser’s Quality System is industry compliant for each industry we serve, robust, stable, and ensures the production of high quality products.

NEW PRODUCT INTRODUCTION

Our NPI center is located close to customers, providing prototyping, verification, and product launch services. The production facility will ramp up to volume or provide contract manufacturing transfer services to our “best cost” locations, in every major region worldwide.

MANUFACTURING

We are the contract electronic manufacturing company of choice for the most renowned technology brands, making the most complex and innovative electronic and mechanical products in the world.

LOGISTICS

Lorser integrates fulfillment and repair services with global supply chain management. This combination gives our customers a complete solution; manufacturing, BTO/CTO, order fulfillment and after market-services.

PCB ASSEMBLY AND SMT

From prototyping, low volume high mix to high volume cost optimized products Lorser provides advanced PCBA and SMT Services in facilities located in Asia & America.

Industries We Serve

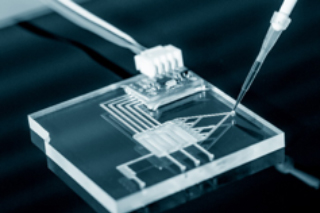

MEDICAL

WE DESIGN, BUILD AND SERVICE COMPLETE MEDICAL SYSTEMS:

• DIAGNOSTIC EQUIPMENT, laboratory and point of use blood diagnostics, molecular diagnostics;

• IMAGING SYSTEMS, design services for key subassemblies and electronics;

• MONITORING AND THERAPY, products for patient monitoring, RF and other therapeutic applications, like RF generators for therapy, and user interfaces for various procedures;

• DEVICES AND DISPOSABLES, high volume consumer medical devices and disposable medical devices.

COMMUNICATIONS

END-TO-END PRODUCT SERVICES: DESIGN, MANUFACTURING, ORDER FULFILMENT AND REPAIR

• PRODUCTS: broadband routers, switches, RF filters and radios, long haul wireless and more;

• TECHNOLOGY design and manufacturing of RF and optical modulators, transceivers, backplanes and PCBs. A unique combination of engineering, technology and manufacturing experience makes us a trusted and valuable supply chain partner.

DEFENSE AND AEROSPACE

For more than 10 years SAA, a Lorser Commercial Partner, has developed, manufactured, qualified and supported high-reliability products for military and commercial aviation, ground tactical and other defense applications, as well as industrial and space flight programs. Capabilities ranging from an experienced multi-disciplinary engineering organization, network centric communications solutions and avionics products, to end-to-end testing, manufacturing, and post-delivery sustainment, SAA and Lorser provide unsurpassed quality and support to the defense and aerospace sector.

PRODUCTS

Voice Recognition Technology

Artificial Intelligence Applications

Machine Learning Applications

HARDWARE: Custom built ADCs, Transceivers, Mother Boards, System-On-Module Solutions

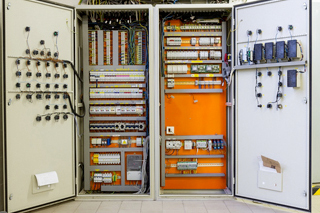

INDUSTRIAL

Large volume capacity EMS provider for contract manufacturing of complex and technologically advanced industrial products. Lorser builds finished products and provides design and contract manufacturing services for enclosures, machining, welded frames and PCBs for a broad range of industrial products:

• Industrial Controls for printers, ATMs, kiosks, gaming systems, integration and testing of complex mechatronics;

• Capital Equipment for semiconductor market

• Power Control Units

• Smart Meters and electric car chargers

• Broad range of inverters and enclosures for renewable energy systems, design, functional testing and burn-in equipment for microinverters

• Complex electronics and control systems for the most advanced elevators and escalators

• Transportation Control Systems, complex PCB assemblies, indoor and outdoor enclosures

• Test and Measurement Equipment Controllers, state of the art RF test equipment for wireless products

COMPUTING AND STORAGE

END-TO-END SERVICES FOR ENTERPRISE COMPUTING, CLOUD STORAGE, AND STORAGE SERVER PRODUCTS TO HELP COMPUTING AND STORAGE OEMs ACCELERATE TIME-TO-MARKET AND SIMPLIFY SUPPLY CHAIN.

Lorser Design and Manufacturing Solutions are tailored for competitive advantage in bandwidth, power consumption, and storage density and include:

• Design and Cost Effective Photosharing Cloud Storage

• High Volume Storage Server Manufacturing

• Rack Scale Cloud Servers

• I/O Intensive Parallel Processor and Storage

• Advanced, High Speed Graphics Processor

• High Performance Computer/Storage Interface Design

Lorser’s Integrated Manufacturing entitles access to design and manufacturing capability for all components and sub-assemblies for computing products including backplanes, power and cooling sub-assemblies, PCBs, PCBAs, servers, processors, racks and interconnects.This vertically integrated approach simplifies systems development and supply chain for OEMs to accommodate BTO (Built to Order), CTO (Configure to Order), and Direct Order Fulfillment.

MULTIMEDIA AND WEARABLES

DESIGN, TECHNOLOGY, MANUFACTURING AUTOMATION

We offer new product design services, systems manufacturing and order fulfilment for home entertainment, personal lifestyle and other multimedia devices that include:

• Set-top boxes, cables and satellite receivers

• Consumer electronics

• Audio and Video Equipment

• Cinematography, Digital Cameras

• Casino Gaming Systems and Electronics

• Global Positioning Systems

• Portable media/audio players, digital audiobooks – turnkey design, plastics, manufacturing, content loading and order fulfilment

• E-book readers and devices

• Point-of-sale terminals, kiosks and automated retail vending systems.

• Motion sensors for lighting, temperature and smart home devices

• Chargers, battery systems and power supplies, Micro Electronics and Miniaturization

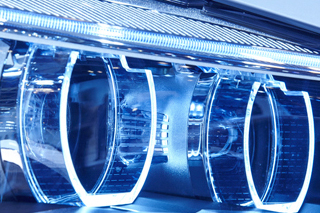

AUTOMOTIVE

Lorser manufactures Automotive Products using a regulatory framework including ADOP (Advanced Product Quality Planning), PPAP (Product Part Approvals), PCN (Part Change Notice) and TC 16949 Certification.

Lorser understands the specific quality requirements of the automotive industry and have incorporated stringent manufacturing and quality procedures based on lean manufacturing, six sigma and zero defect initiatives. Automotive OEMs and suppliers come to Lorser for advise in Functional Safety or Design and Manufacturability.

The products manufactured include:

• Body controllers and “Intelligent Testing” approach, to eliminate latent defects by activating and testing for both typical and known failure modes during production testing

• Meter Clusters and Steering Column Electronics

• Climate Control and Blower Assemblies

• Advanced Driver Assistance Systems

• Park Assist and Intelligent Sensors

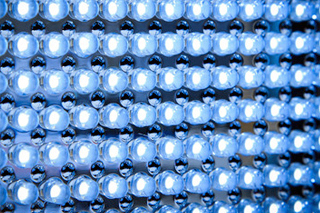

• LED Lighting Systems

• Head Units, GPS and Infotainment Systems

• Electric Vehicle Control Units and Inverters

• Remote Controls and Toll Tags

• Communication Controls, Amplifiers, and Tuners

END-TO-END SERVICES

Lorser provides the following End-to-End Services :

• Design and Automotive Electric Engineering Services

• Test System Development

• Supply Chain Design

• Functional Safety Analysis

• New Product Introduction

• Product and Process Qualification

• Quick Turn Prototypes

• Component Engineering

• Reliability and Value engineering

Key Automobile and Vehicle Electronics Elements

• RF, Optical Memory Components, Cable Assemblies, PCBA, PCB, Subassembly and finished product.

Complex Technology and Manufacturing Automation

• The complex technology needed to realize advanced driver assistance systems and the driverless car includes communications, sensors, multimedia and high density electronics.

OIL AND GAS INDUSTRY

Lorser offers product design support and a vast array of manufacturing services from precision modeling of components to assembly and test of major turnkey assemblies. These includes electronics, mechanical, software testing:

• Systems Engineering: requirements, development and traceability, system analysis, integration testing and verification

• Mechanical Engineering: designs for harsh oil environment with motors, pumps, valves, hydraulics, strength analysis, sensor packaging and integration

• Electrical engineering: embedded processors - controllers, DSPs, motor controllers; sensors measurement and signal conditioning, data acquisition, storage and retrieval, high-temperature designs

• Software Engineering: all the popular programming languages for embedded processors: controllers and DSPs, National Instruments Lab View Measurement and Control Programming Language

Contact us for a free consultation.

Premium Circuit Board Assembly and System-Level Manufacturing.

Lorser Industries Inc. provides design, assembly, manufacturing, and system-level manufacturing and integration. We accommodate prototyping, small, medium, and large volume orders in our state-of-the-art facilities configured for lean and automated production. Our clients agree that high-quality and prompt service is the reason they choose Lorser

We serve clients in Communications, Industrial, Medical, Automotive, Multimedia, Defense and Aerospace, Computing & Storage, and Oil & Gas.

Request more information.

Lorser Industries Inc.

Premium Circuit Board Manufacturing.

Tour Our Facility

2714 Loker Ave W

Suite 100-120

Carlsbad, California 92010

United States

Hours of Operation

Monday - Friday: By Appointment

6:30 am - 3:00 pm

Saturday, Sunday: Closed

Hours of Operation

Monday - Friday: By Appointment

6am - 2:30pm

Saturday, Sunday: Closed

Tour Our Facility

2714 Loker Ave W

Suite 100-120

Carlsbad, California 92010

United States